Anne Beers Elementary School Playground Design

Anne Beers is an elementary school in Washington, D.C. Custom Park Surfacing worked with HGRM to design a new playground, using poured rubber for fall attenuation and to provide a pleasant brightly colored play area to engage and delight the children of the school and the surrounding community.

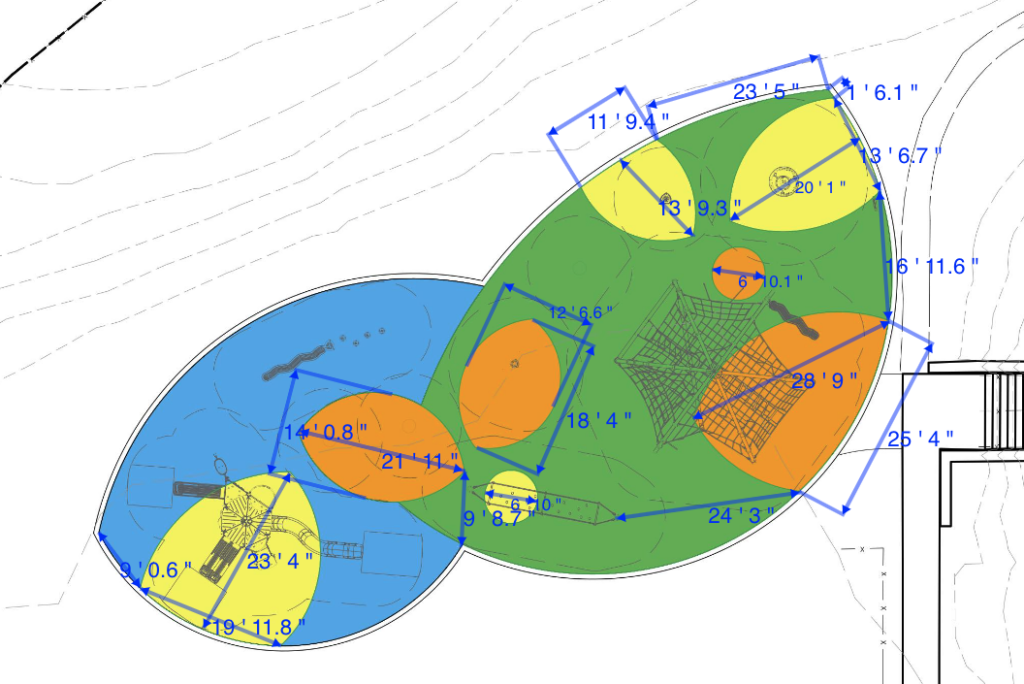

This article is one of three that shows the process that we use when installing poured rubber surfaces in play areas. First off is the plan — this is developed by the contractor with our technical input (technical sheets on all the products can be downloaded here.)

The plan indicates the various areas and the colored rubber associated with each.

Site prep – crushed stone aggregate

First the site surface is prepped so that the poured rubber can be installed. The base is aggregate crushed stone — the depth of the stone depends on the fall attenuation specifics required — the higher the potential fall, the less the aggregate base in terms of depth.

Base Rubber Layer

Once that is compacted, we lay the base rubber surface — rubber chunks held together by a polyurethane binder, the same binder we use for the colored rubber surfaces.

This is the view of the playground from the other side, showing more of the aggregate crushed stone base.

Laying out the design

Once the base rubber layer is down, we paint lines on that base to indicate the smaller colored areas.

Initial poured rubber installation — smaller areas first

Those smaller areas are then laid in and allowed to cure overnight so the rest of the poured rubber can be installed.

The next article will look at the final installation of the larger area of poured rubber for the Anne Beers playground in DC.

If you’re interested in poured rubber surfacing, for play areas or other uses, please contact us today!